-

[Physical Review Fluids] Electric-Field-Mediated Jet Formation from the Bubble Bursting above a Fr…

87. Xie, Yufei, Hao Chen, Yihan Wang, and Haisheng Fang, Electric-Field-Mediated Jet Formation from the Bubble Bursting above a Free Surface at Low Ohnesorge Number, Physical Review Fluids, 10.3 (2025), 033701

更新于:2025/03/20 -

[Physics of Fluids] The Maximum Spreading of a Shear-Thinning Fluid Droplet Impacting on Solid Sur…

86. Sang, Xianqian, Tao An, Yihan Wang, Hao Chen, and Haisheng Fang, The Maximum Spreading of a Shear-Thinning Fluid Droplet Impacting on Solid Surfaces, Physics of Fluids, 37.2 (2025)

更新于:2025/03/20 -

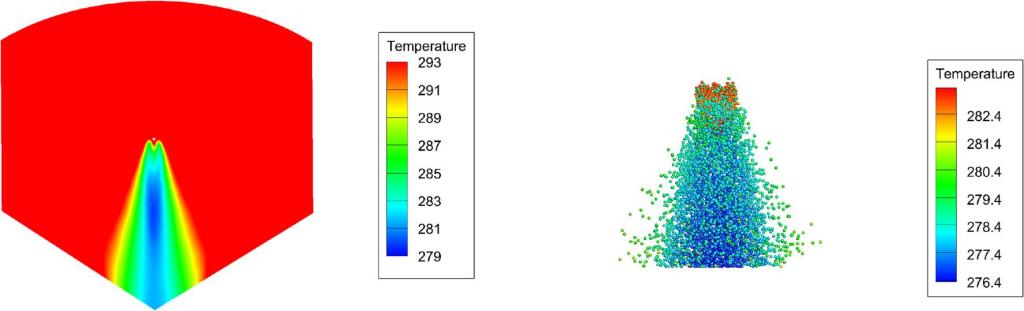

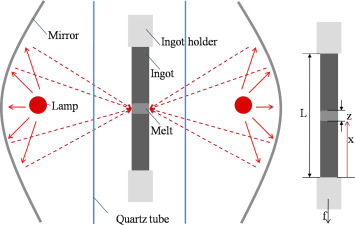

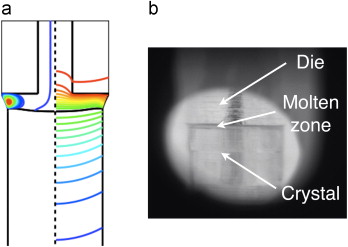

[International Communications in Heat and Mass Transfer] Solidification Process of Hollow Metal Dr…

85. An, Tao, Hao Chen, Xianqian Sang, Yuchen Wang, and Haisheng Fang, Solidification Process of Hollow Metal Droplets Impacting a Substrate, International Communications in Heat and Mass Transfer, 159.PC (2024), 108252

更新于:2024/11/18 -

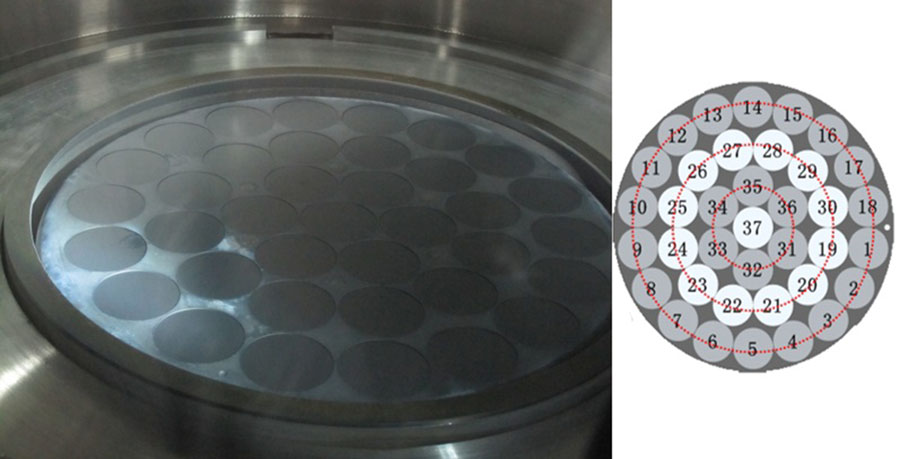

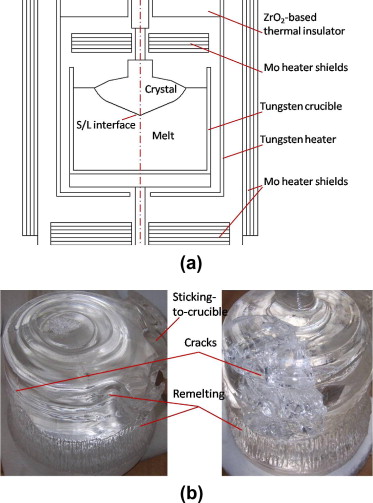

[Surface and Coatings Technology] Improvement of Titanium Film Uniformity by Magnetron Sputtering …

84. An, Qiaoru, Taoran Jiang, and Haisheng Fang, Improvement of Titanium Film Uniformity by Magnetron Sputtering with Electromagnetic Coil Design, Surface and Coatings Technology, 494.P1 (2024), 131365https://doi.org/10.1016/j.surfcoat.2024.131365

更新于:2024/09/23 -

[Journal of Fluid Mechanics] Modelling the First Droplet Emission from an Electrified Liquid Menis…

83. Chen, Hao, Guozhen Wang, Tao An, Zhouping Yin, and Haisheng Fang, Modelling the First Droplet Emission from an Electrified Liquid Meniscus Hanging at the Nozzle Tip, Journal of Fluid Mechanics, 987 (2024), A38

更新于:2024/06/24 -

[International Journal of Heat and Mass Transfer] Effect of Substrate Temperature on the Deformati…

82. An, Tao, Hao Chen, Yuchen Wang, and Haisheng Fang, Effect of Substrate Temperature on the Deformation of Liquid Metal Droplets during Spreading and Solidification, International Journal of Heat and Mass Transfer, 223.September 2023 (2024), 125241

更新于:2024/02/20 -

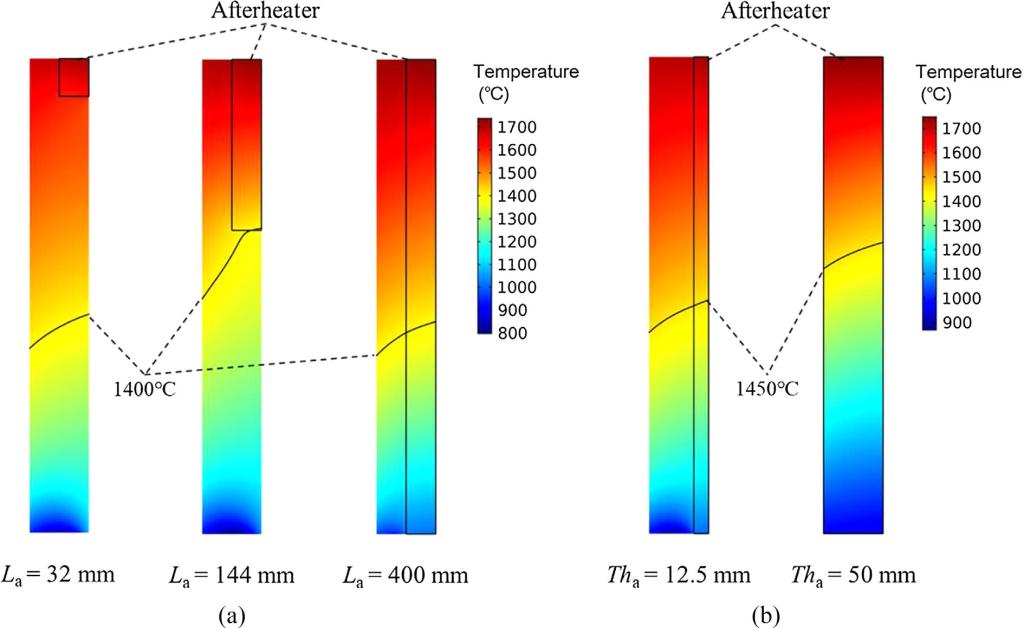

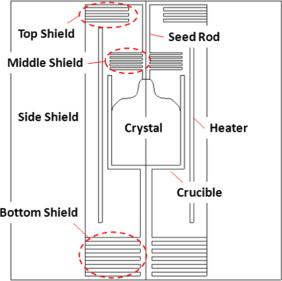

[Journal of Non-Crystalline Solids] Effects of Annealing on Thermal Stress Generation during the C…

81. Yin, Suping, Chengshuai Li, Haisheng Fang, and Qianli Ma, Effects of Annealing on Thermal Stress Generation during the Cooling Process of Large-Size Silica Glass, Journal of Non-Crystalline Solids, 628.November 2023 (2024), 122857

更新于:2024/02/20 -

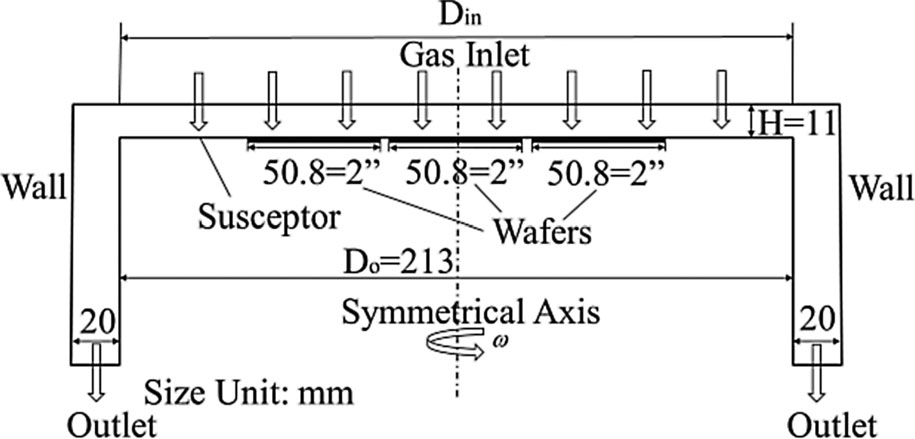

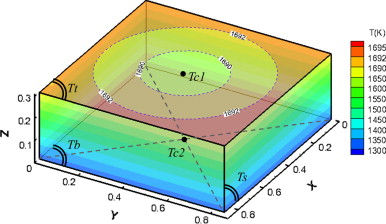

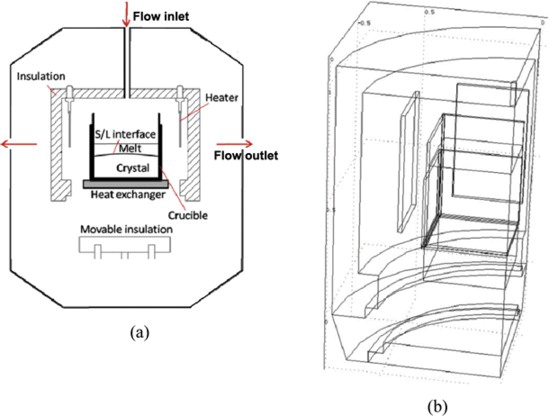

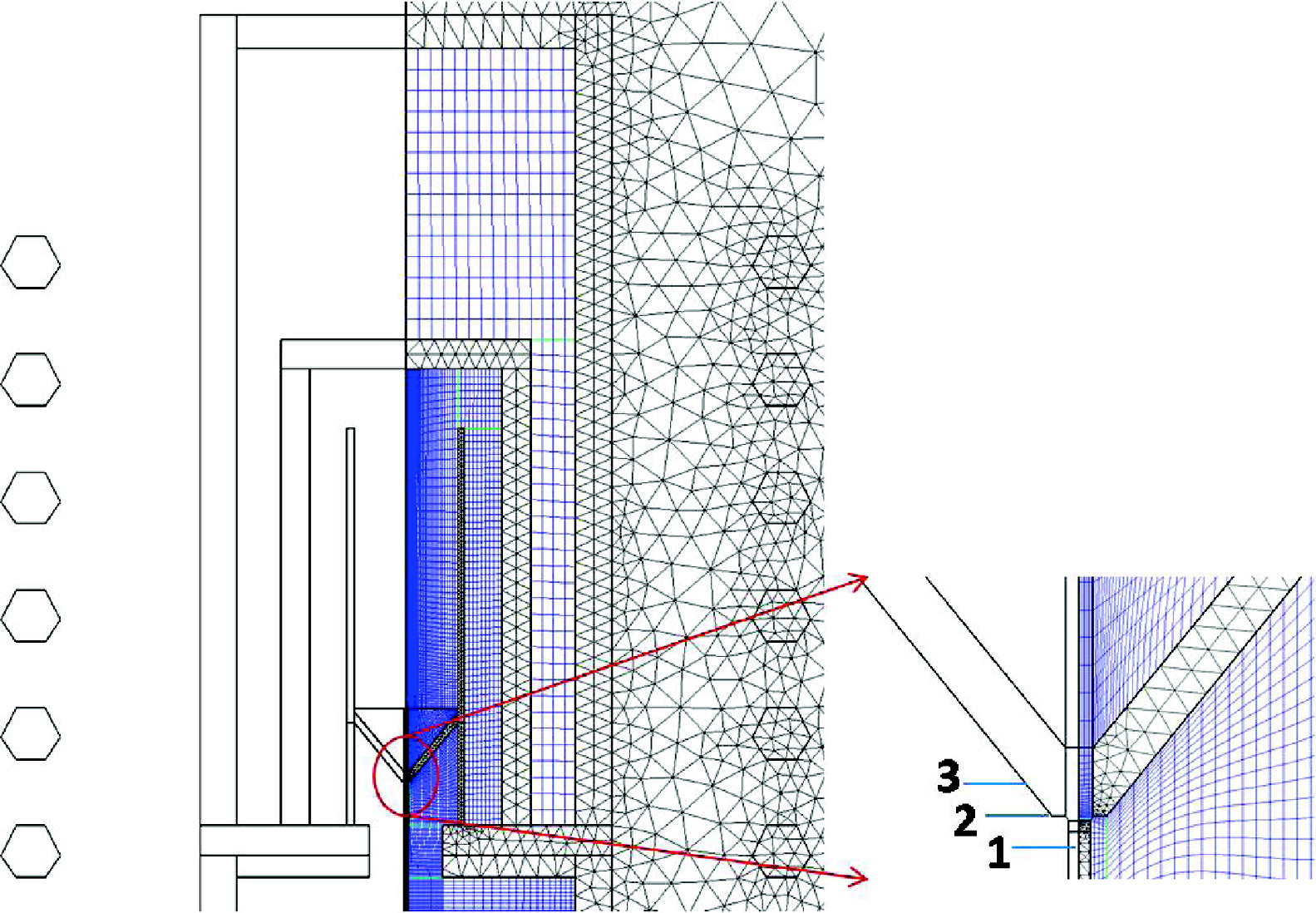

[Crystal Research and Technology] Analysis of Influencing Factors on Silicon Epitaxial Growth in H…

80. Li, Chaozhong, Chengshuai Li, Hang Jiang, Hao Chen, and Haisheng Fang, Analysis of Influencing Factors on Silicon Epitaxial Growth in Horizontal Single-Wafer Reactor through Orthogonal Test, Crystal Research and Technology, 2300237 (2024), 1–11

更新于:2024/02/20 -

[Surface and Coatings Technology] Copper Target Erosion during Unbalanced Magnetron Sputtering und…

79. An, Qiaoru, Jie Li, and Haisheng Fang, Copper Target Erosion during Unbalanced Magnetron Sputtering under Different Electromagnetic Fields, Surface and Coatings Technology, 477.December (2023), 130360

更新于:2024/01/10 -

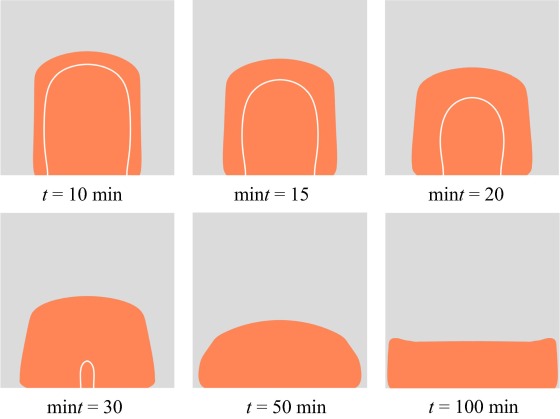

[International Journal of Applied Glass Science] Modeling and Optimization of the Sagging Process …

78. Li, Chengshuai, Suping Yin, Qianli Ma, and Haisheng Fang, Modeling and Optimization of the Sagging Process for Large-Size and High-Purity Silica Glass Synthesis, International Journal of Applied Glass Science, May, 2023, 1–15

更新于:2024/01/10 -

[Applied Surface Science] Monte Carlo simulation of deposition uniformity in the triple-target mag…

77. J. Li, Q. An, H. Fang. Monte Carlo simulation of deposition uniformity in the triple-target magnetron co-sputtering system. Applied Surface Science. Elsevier B.V., 2024, 646(November 2023): 158914

更新于:2023/12/07 -

[Ceramics International] SiO2 soot preform sintering process for the synthesis of large-size and h…

76. C. Li, Q. Ma, S. Yin, H. Fang. SiO2 soot preform sintering process for the synthesis of large-size and high-purity silica glass. Ceramics International. Elsevier Ltd, 2023, 50(1PA): 865–882

更新于:2023/12/07 -

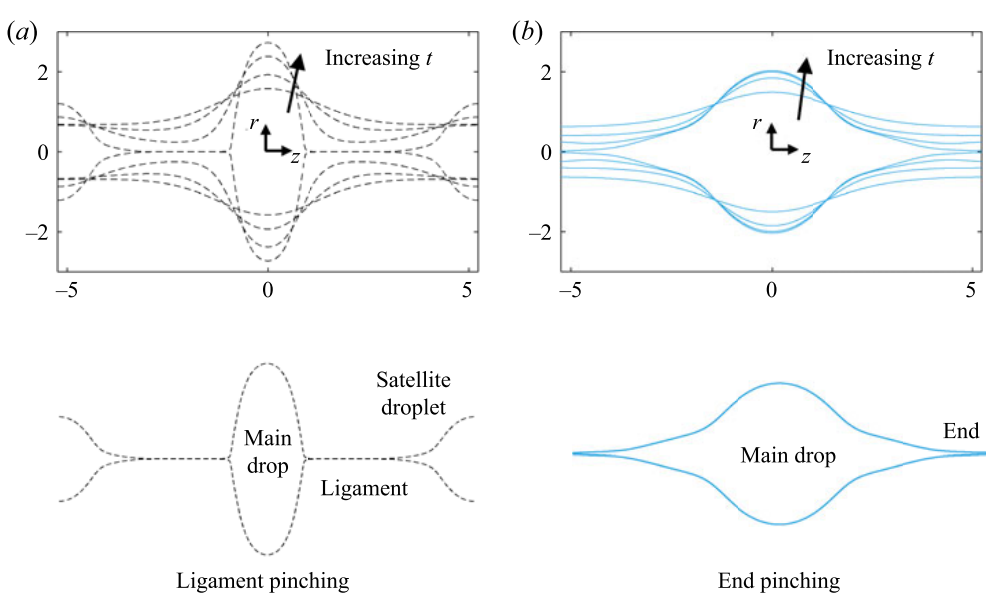

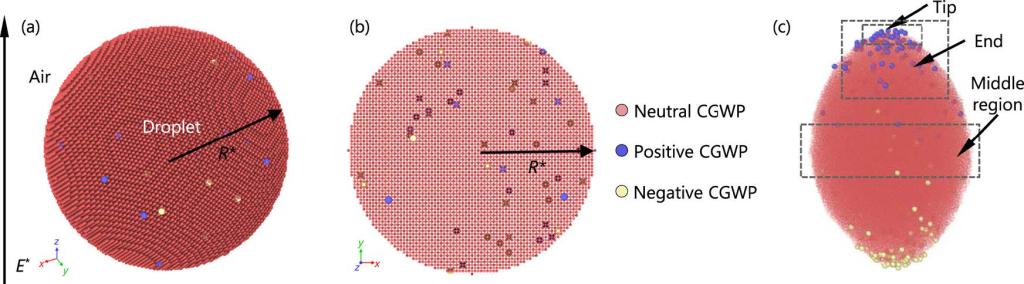

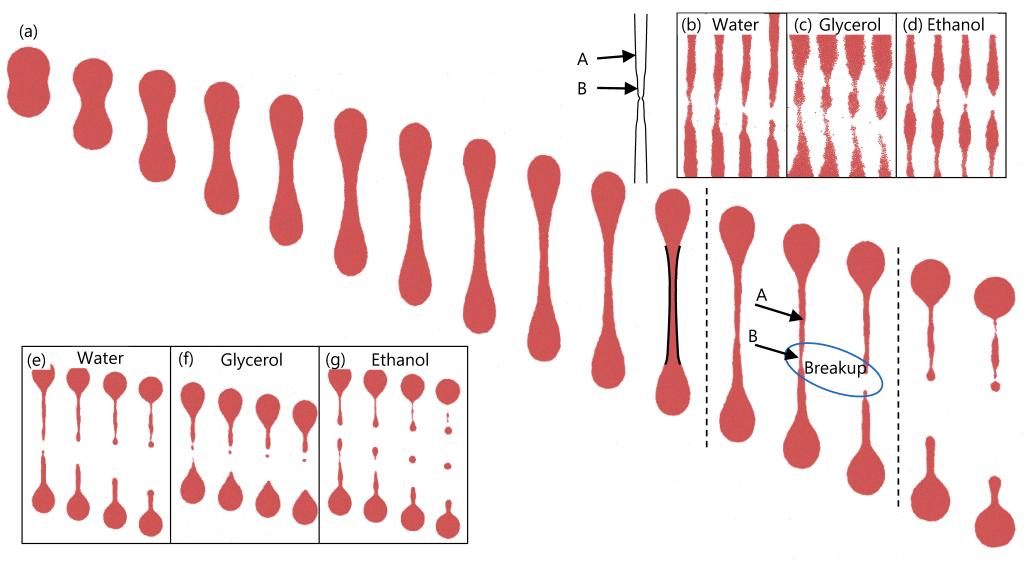

[Journal of Fluid Mechanics] Electrohydrodynamic-induced partial coalescence between a droplet and…

75. H. Chen, W. Chen, Z. Yin, H. Fang. Electrohydrodynamic-induced partial coalescence between a droplet and a liquid–air interface. Journal of Fluid Mechanics. 2023, 963: A39

更新于:2023/06/05 -

[Applied Thermal Engineering] Numerical study of a novel concentrator photovoltaic-membrane distil…

74. H. Zhang, X. Li, Z. Han, H. Fang. Numerical study of a novel concentrator photovoltaic-membrane distilled plate-type seawater desalination structure Cooling channel. Applied Thermal Engineering. 2023, 227, 120328.

更新于:2023/03/15 -

[Journal of the American Ceramic Society] Effects of injection conditions on temperature and compo…

73. C. Li, H. Zhang, Q. Ma, H. Fang. Effects of injection conditions on temperature and component distributions in a CVD furnace for large-size silica glass. Journal of the American Ceramic Society. 2023(December 2022): 1–17

更新于:2023/02/19 -

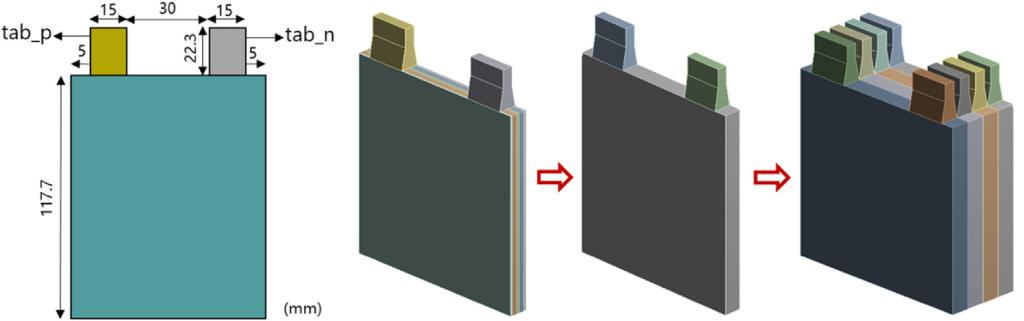

[Energies] Cooling Optimization Strategy for a 6s4p Lithium-Ion Battery Pack Based on Triple-Step …

72. H. Zhang, H. Chen, H. Fang. Cooling Optimization Strategy for a 6s4p Lithium-Ion Battery Pack Based on Triple-Step Nonlinear Method. Energies. 2023, 16(1)

更新于:2023/02/19 -

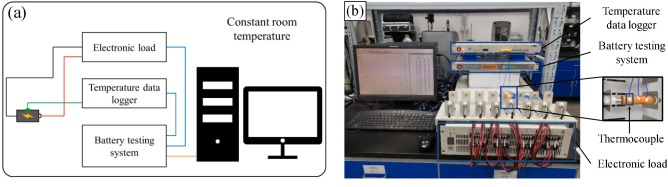

[Journal of Energy Research] Analysis of prismatic lithium-ion battery degradation based on an ele…

71. H. Zhang, C. Li, H. Chen, 2022. Analysis of prismatic lithium-ion battery degradation based on an electrochemical-thermal-degradation model.International Journal of Energy Research. 1–24.

更新于:2022/09/06 -

[Physics of Fluids] Predicting the lifetimes of evaporating droplets in ordered arrays

70. Chen, H., An, Q., Zhang, H., Li, C., Fang, H., Yin, Z., 2022. Predicting the lifetimes of evaporating droplets in ordered arrays. Phys. Fluids 34, 082010.

更新于:2022/09/06 -

[Crystal Research and Technology] Study of Dislocation Bending During Film Growth by a Multiscale …

69. Q. An, Q. Nie, S. Liu, H. Fang. Study of Dislocation Bending During Film Growth by a Multiscale Scheme. Crystal Research and Technology. 2022, 2100214: 2100214

更新于:2022/04/25 -

[Physics of Fluids] Probing the coalescence of non-Newtonian droplets on a substrate

68. H. Chen, X. Pan, Q. Nie, Q. Ma, H. Fang, and Z. Yin,"Probing the coalescence of non-Newtonian droplets on a substrate", Phys. Fluids 34, 032109 (2022).

更新于:2022/03/24 -

[Physics of Fluids] Stability of line shapes in inkjet printing at low substrate speeds

67. X. Gao, H. Chen, Q. Nie, and H. Fang,"Stability of line shapes in inkjet printing at low substrate speeds", Phys. Fluids 34, 032002 (2022).

更新于:2022/03/24 -

[International Journal of Heat and Mass Transfer] Mechanism study on spreading dynamics of nanoflu…

66. Z. Liu, S. Li, X. Pan, and H. Fang,"Mechanism study on spreading dynamics of nanofluids droplet coupled with thermal evaporation", Int. J. Heat Mass Transf. 183, 122172 (2022).

更新于:2022/03/24 -

Effects of charge relaxation on the electrohydrodynamic breakup of leaky-dielectric jets

65. Nie, Q., Li, F., Ma, Q., Fang, H. & Yin, Z. Effects of charge relaxation on the electrohydrodynamic breakup of leaky-dielectric jets. J. Fluid Mech. 925, (2021).

更新于:2021/10/09 -

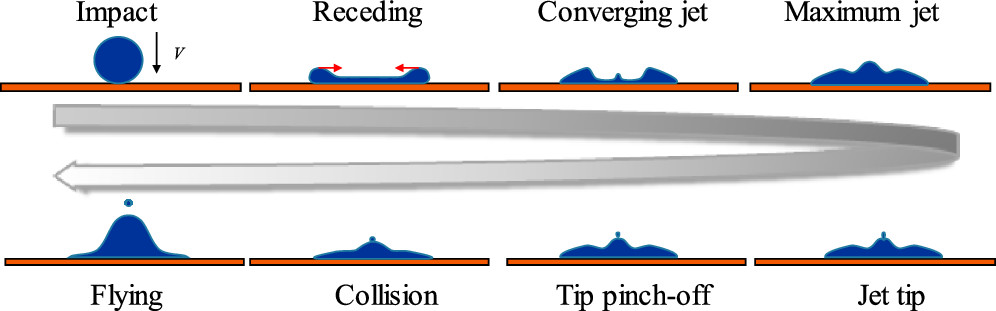

Receding Dynamics of Droplet Deposition on a Smooth Surface from a Central Jet to Secondary Drople…

60. Liu, Z., Pan, X., Ma, Q. & Fang, H. Receding Dynamics of Droplet Deposition on a Smooth Surface from a Central Jet to Secondary Droplet Emission. Langmuir 36, 15082–15093 (2020).

更新于:2021/05/23 -

Designing working diagrams for electrohydrodynamic printing

64. Nie, Q. et al. Designing working diagrams for electrohydrodynamic printing. Chem. Eng. Sci. 240, 116661 (2021)

更新于:2021/05/23 -

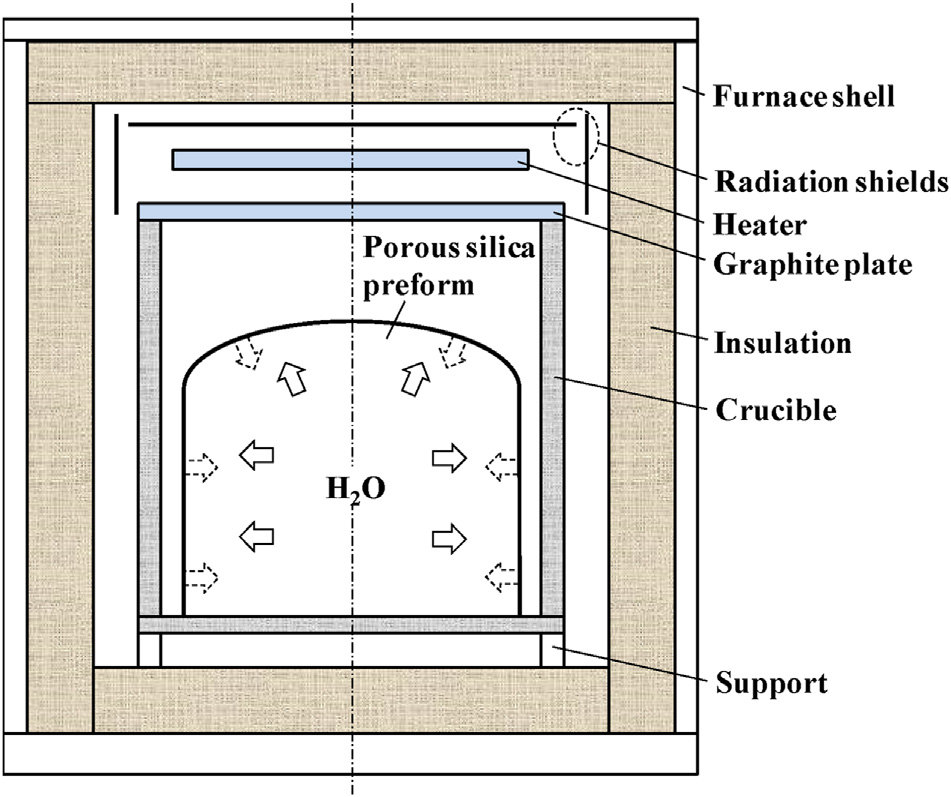

Effects of thermal environment on dehydroxylation of porous silica preform in two-step CVD synthes…

63. Ma, Q., Li, C., Shang, C., Zheng, L. & Fang, H. Effects of thermal environment on dehydroxylation of porous silica preform in two‐step CVD synthesis. J. Am. Ceram. Soc. 104, 3105–3118 (2021)

更新于:2021/05/23 -

On the characteristics analysis and tab design of an 18650 type cylindrical LiFePO4 battery

62. Li, C., Zhang, H., Zhang, R., Lin, Y. & Fang, H. On the characteristics analysis and tab design of an 18650 type cylindrical LiFePO4 battery. Appl. Therm. Eng. 182, 116144 (2021).

更新于:2021/05/23 -

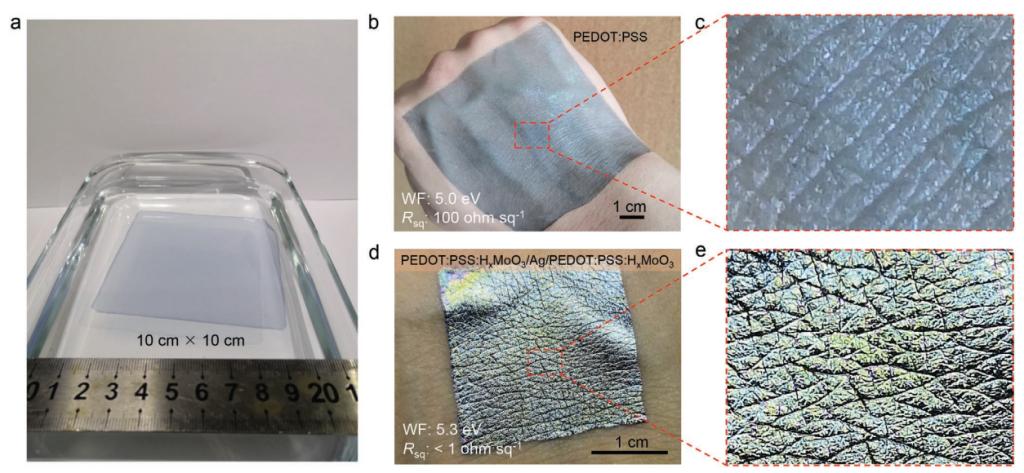

Marangoni Force Assisted Spreading and Printing of Nanometer-Thick Polymer Films for Ubiquitous Op…

61. Xie, C. et al. Marangoni Force Assisted Spreading and Printing of Nanometer‐Thick Polymer Films for Ubiquitous Optoelectronic Devices. Adv. Mater. Technol. 2100181 (2021) doi:10.1002/admt.202100181.

更新于:2021/05/23 -

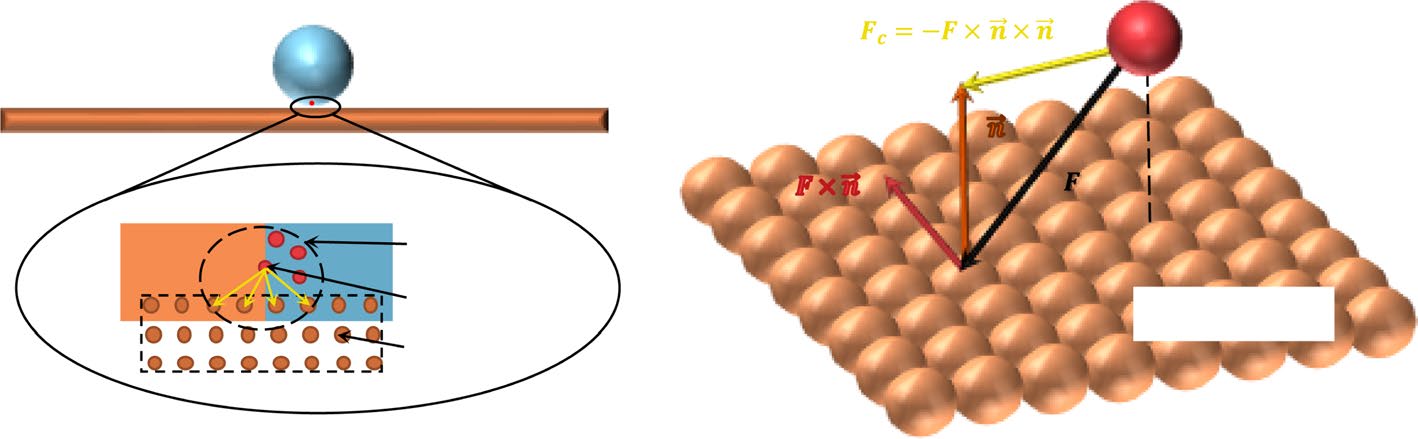

Dynamic behavior of droplets on confined porous substrates: A many-body dissipative particle dynam…

59. Chen, H., Nie, Q. & Fang, H. Dynamic behavior of droplets on confined porous substrates: A many-body dissipative particle dynamics study. Phys. Fluids 32, 102003 (2020).

更新于:2020/09/24 -

Numerical modeling of sintering and dehydroxylation of porous silica preform for low-hydroxyl sili…

58. Qianli Ma, Lili Zheng, Guojun Zhang, Chunli Shang, Haisheng Fang*, Numerical modeling of sintering and dehydroxylation of porous silica preform for low-hydroxyl silica glass fabrication, Ceramics International 46(1) (OCT 2020) 23067-23083.

更新于:2020/09/24 -

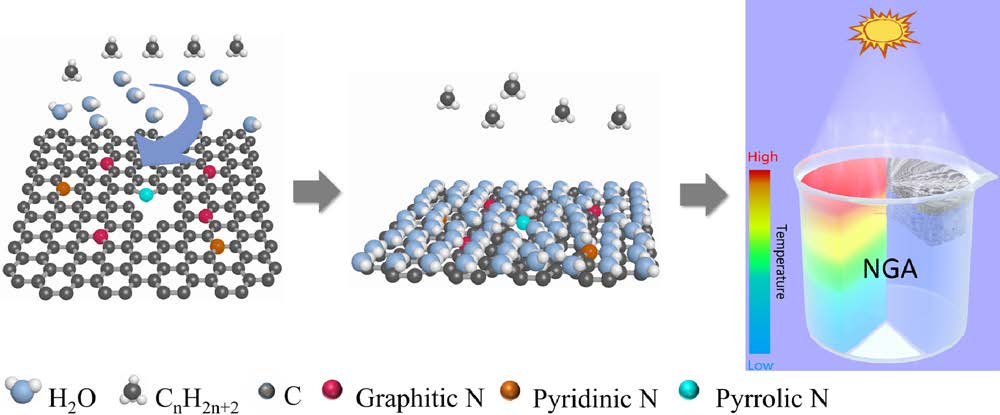

Nitrogen-Doped Unusually Superwetting, Thermally Insulating, and Elastic Graphene Aerogel for Effi…

57. Xin Deng, Qichun Nie, Yu Wu, Haisheng Fang, Peixin Zhang, Yangsu Xie*, Nitrogen-Doped Unusually Superwetting, Thermally Insulating, and Elastic Graphene Aerogel for Efficient Solar Steam Generation, ACS Appl. Mater. Interfaces 12(23) (JUN 2020) 26200-26212

更新于:2020/09/24 -

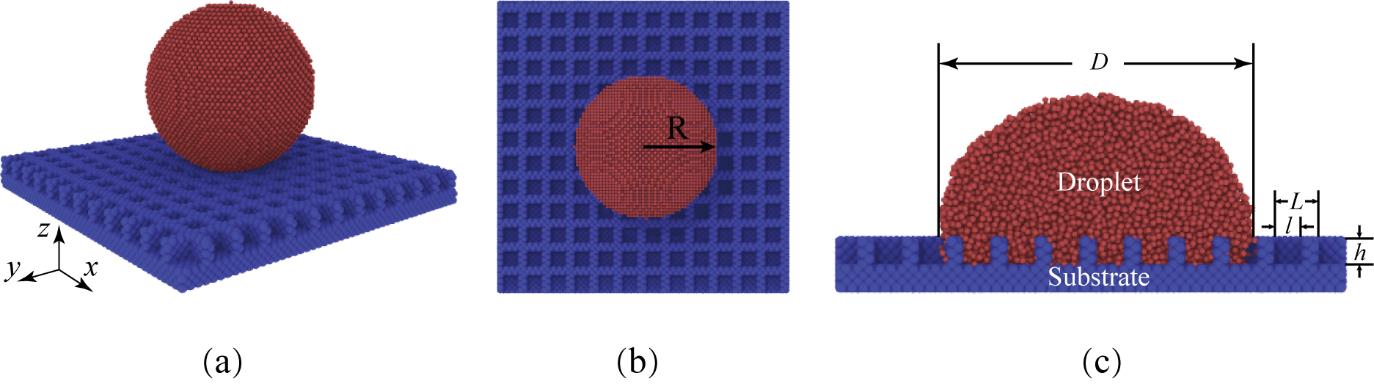

Many-body dissipative particle dynamics simulation of Newtonian and Non-Newtonian nanodroplets spr…

56. Hao Chen, Qichun Nie, Haisheng Fang*, Many-body dissipative particle dynamics simulation of Newtonian and Non-Newtonian nanodroplets spreading upon flat and textured substrates, Applied Surface Science 519 (JUL 2020) 146250.

更新于:2020/09/24 -

Thermal analysis of a 6s4p Lithium-ion battery pack cooled by cold plates based on a multi-domain …

55. Hongya Zhang, Chengshuai Li, Runjie Zhang, Yixin Lin, Haisheng Fang*, Thermal analysis of a 6s4p Lithium-ion battery pack cooled by cold plates based on a multi-domain modeling framework, Applied Thermal Engineering 173 (JUN 2020) 115216

更新于:2020/09/24 -

Four Modes of Droplet Permeation through a Micro-pore with a T-Shaped Junction during Spreading

54. Zhongyi Liu, Siqi Li, Haisheng Fang*, Xiaolong Pan, Four Modes of Droplet Permeation through a Micro-pore with a T-Shaped Junction during Spreading, Transport in Porous Media 132(1) (MAR 2020) 219-240

更新于:2020/09/24 -

Theoretical Uniformity Analysis and Improvement of Spray Deposition by Mixing Nozzles with Heating…

53. Xuran Dong, Xiaolong Pan, Xianxian Gao, Haisheng Fang*, Theoretical Uniformity Analysis and Improvement of Spray Deposition by Mixing Nozzles with Heating Conditions, Coatings 10(1) (JAN 2020) 81

更新于:2020/09/24 -

Large deformation of a conductive nanodroplet in a strong electric field

52. Qichun Nie, Yongan Huang, Zhouping Yin*, Haisheng Fang*, Large deformation of a conductive nanodroplet in a strong electric field, Physics of Fluids 32(2) (FEB 2020) 022006

更新于:2020/09/24 -

The Effects of Heating Conditions on the Spray Uniformity of the Mixing Nozzle

51. Xuran Dong, Yonghong Zhong, Haisheng Fang*, The Effects of Heating Conditions on the Spray Uniformity of the Mixing Nozzle, Transactions On Electrical And Electronic Materials 21(2) (APR 2020) 208-216. (EI)

更新于:2020/09/24 -

Theoretical design of inkjet process to improve delivery efficiency

50. Yonghong Zhong, Xuran Dong, Zhouping Yin, Haisheng Fang*, “Theoretical design of inkjet process to improve delivery efficiency”, Journal of Applied Fluid Mechanics (2020).

更新于:2019/09/07 -

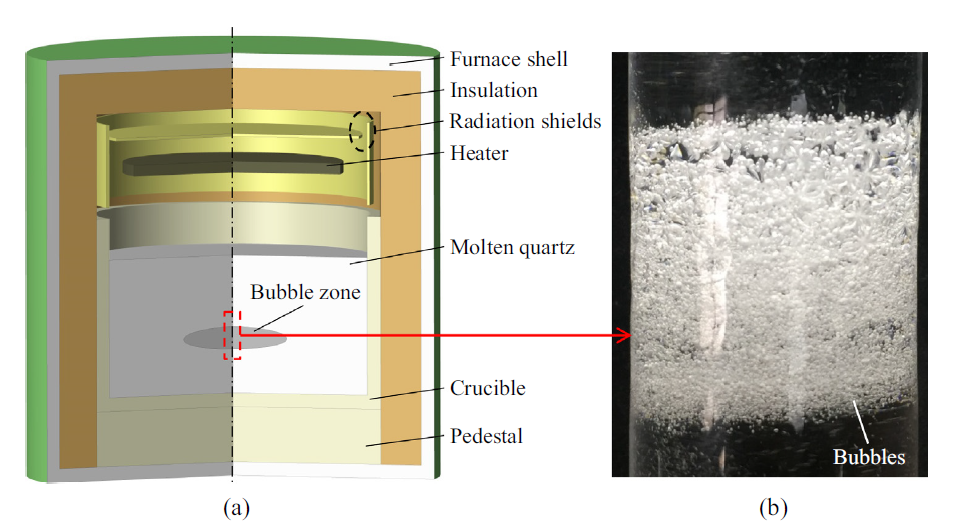

A novel method for accelerating bubble rising in highly viscous molten quartz

49. Ma, Q., Li, C., Zhang, G. & Fang, H. A novel method for accelerating bubble rising in highly viscous molten quartz. Int. J. Heat Mass Transf. 138, 1359–1367 (2019).

更新于:2019/05/12 -

A combined Lagrangian and Eulerian method for simulating the melting process of quartz glass

48. Liu, Z., Ma, Q., Fang, H. & Zhang, G. A combined Lagrangian and Eulerian method for simulating the melting process of quartz glass. Eng. Anal. Bound. Elem. 105, 312–320 (2019).

更新于:2019/05/12 -

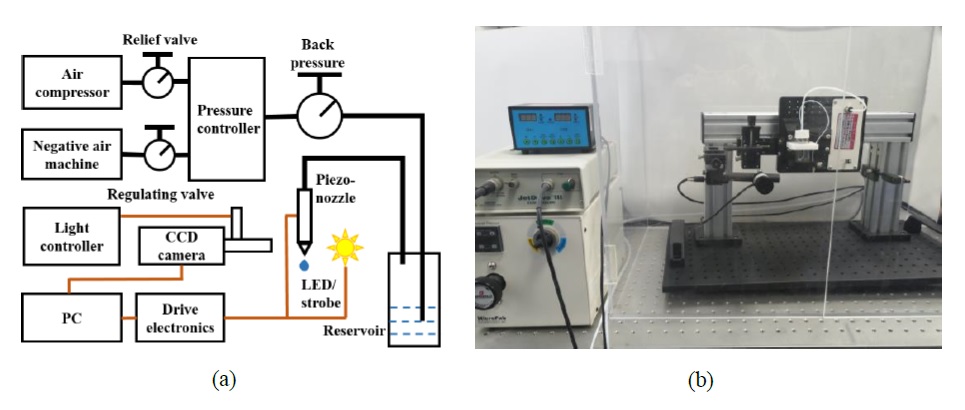

Deformation characteristics of a single droplet driven by a piezoelectric nozzle of the drop-on-de…

47. Wang, S., Zhong, Y. & Fang, H. Deformation characteristics of a single droplet driven by a piezoelectric nozzle of the drop-on-demand inkjet system. J. Fluid Mech. 869, 634–645 (2019).

更新于:2019/05/08 -

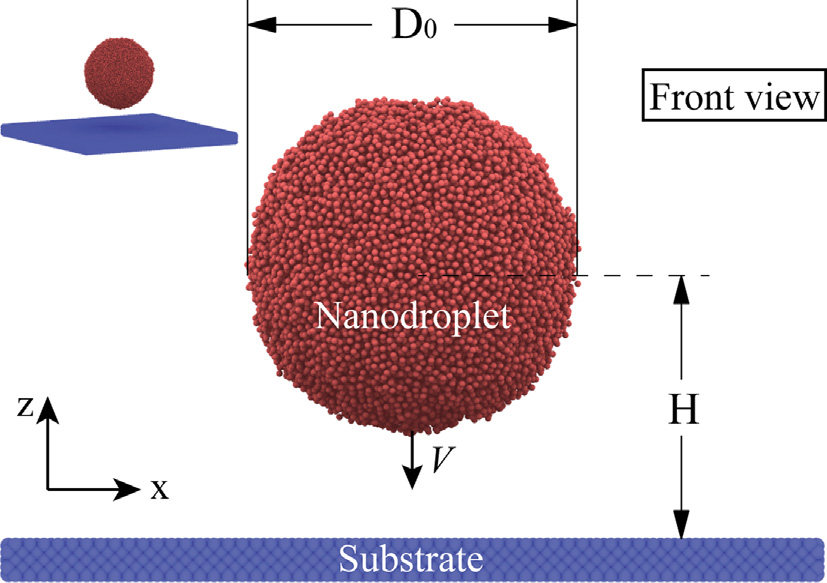

Study of a nanodroplet breakup through many-body dissipative particle dynamics

46. Nie, Q., Zhong, Y. & Fang, H. Study of a nanodroplet breakup through many-body dissipative particle dynamics. Phys. Fluids 31, 042007 (2019).

更新于:2019/05/08 -

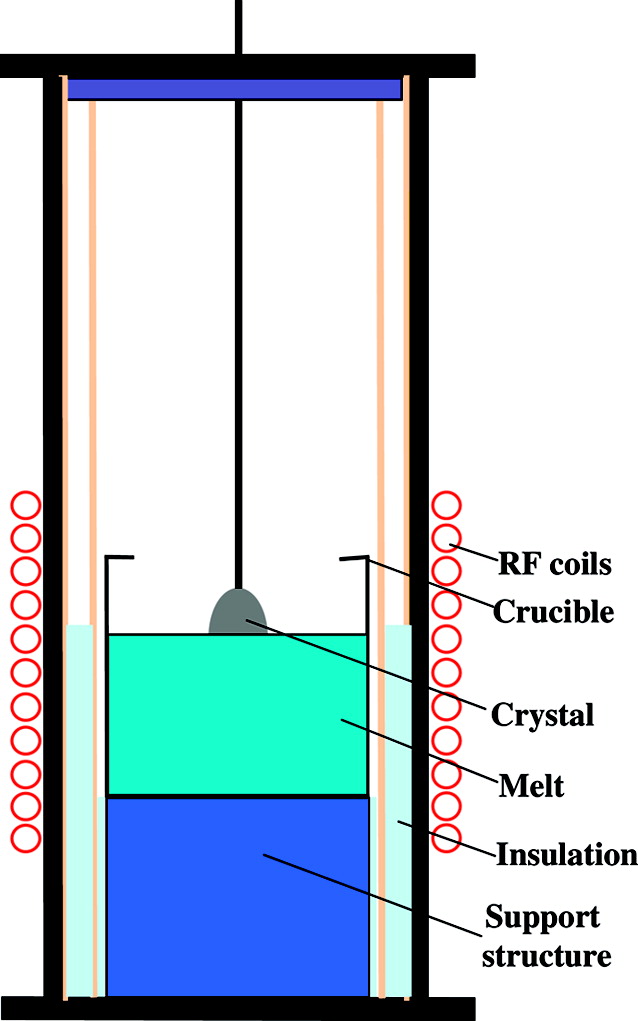

Thermal optimization of induction-heated pulling-down furnace for quartz glass rod fabrication

45. Q. Ma, Z. Liu, Y. Zhong, Y. Lang, X. Liu, and H. Fang, “Thermal optimization of induction-heated pulling-down furnace for quartz glass rod fabrication,” Appl. Therm. Eng., vol. 141, pp. 1–9, Aug. 2018

更新于:2018/09/07 -

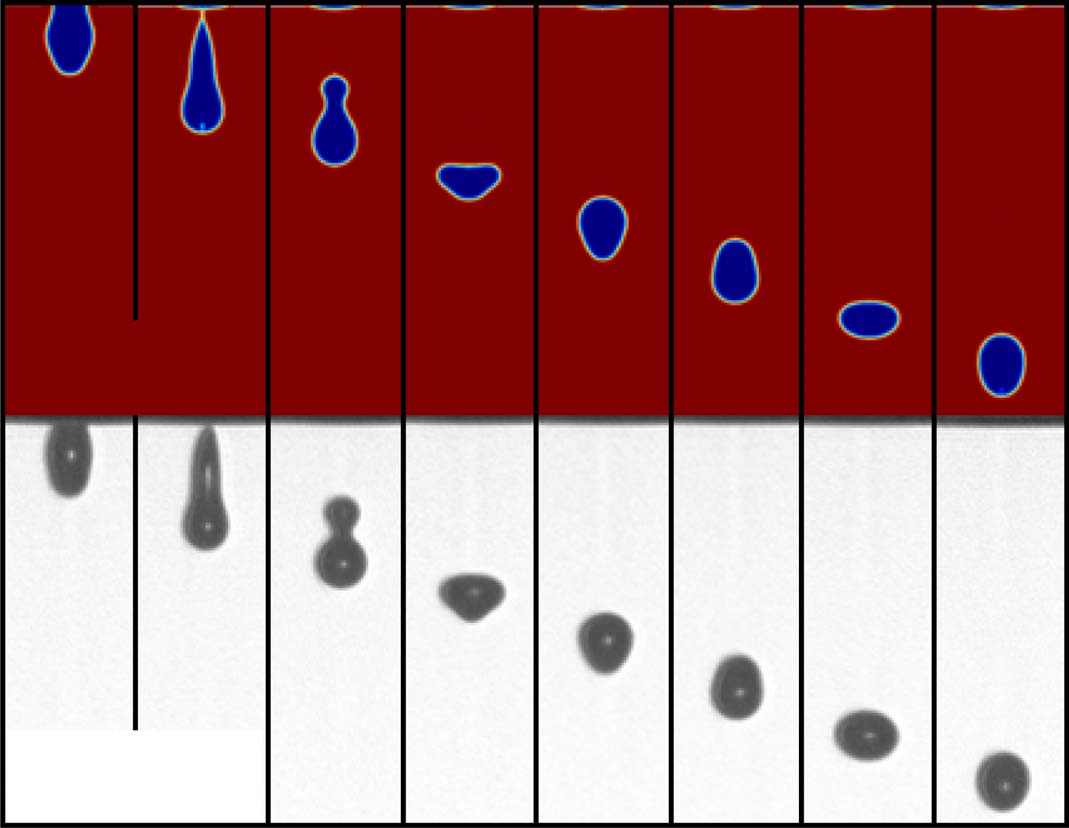

Analysis of droplet stability after ejection from an inkjet nozzle

44. Zhong, Y., Fang, H., Ma, Q., & Dong, X. (2018). Analysis of droplet stability after ejection from an inkjet nozzle. Journal of Fluid Mechanics, 845, 378-391. doi:10.1017/jfm.2018.251

更新于:2018/05/02 -

Defect analysis of the LED structure deposited on the sapphire substrate

43. Nie, Q., Jiang, Z., Gan, Z., Liu, S., Yan, H., Fang, H. Defect analysis of the LED structure deposited on the sapphire substrate (2018) Journal of Crystal Growth, 488, pp. 1-7. DOI: 10.1016/j.jcrysgro.2018.02.011

更新于:2018/05/02 -

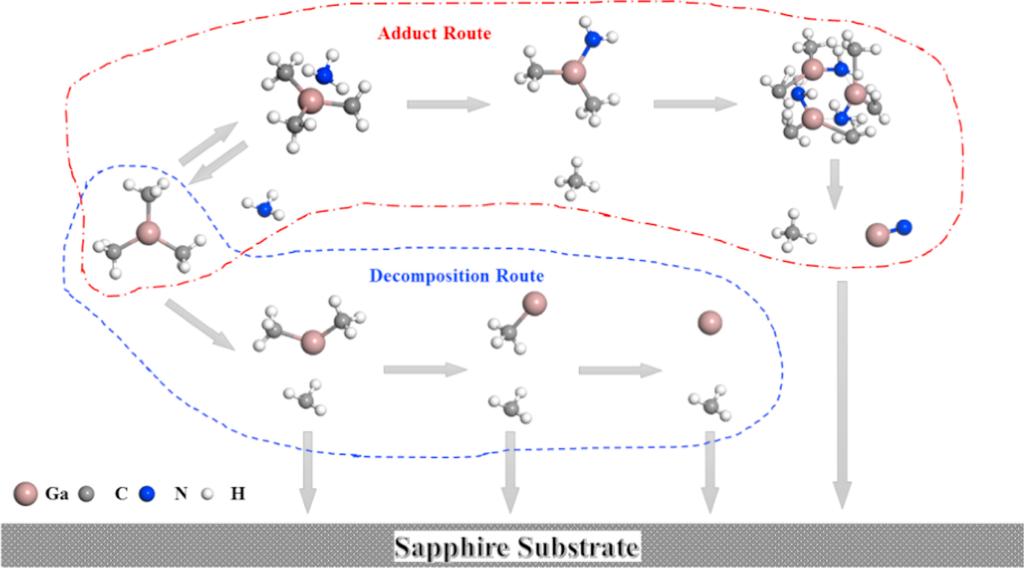

Influences of growth parameters on the reaction pathway during GaN synthesis

42. Z. Zhang, Z. Liu, H. Fang, Influences of growth parameters on the reaction pathway during GaN synthesis, Journal of Crystal Growth. 482 (2018) 44–55. doi:10.1016/j.jcrysgro.2017.11.002.

更新于:2018/03/06 -

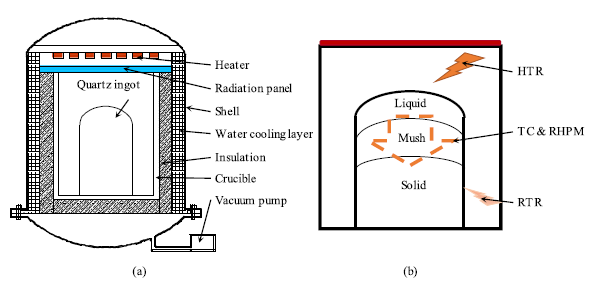

Modeling and optimization of porous silica ingot melting during quartz glass synthesis

41. Q. Ma, H. Fang, Z. Liu, S. Wang, Modeling and optimization of porous silica ingot melting during quartz glass synthesis, Applied Thermal Engineering. 131 (2018) 786–792. doi:10.1016/j.applthermaleng.2017.12.062

更新于:2018/03/06 -

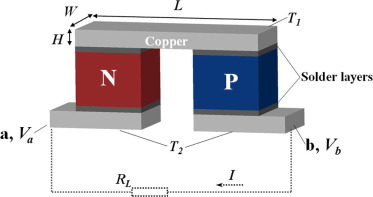

Theoretical analysis and design optimization of thermoelectric generator

40. Ma, Q., Fang, H. & Zhang, M. Theoretical analysis and design optimization of thermoelectric generator. Appl. Therm. Eng. 127, 758–764 (2017).

更新于:2017/12/19 -

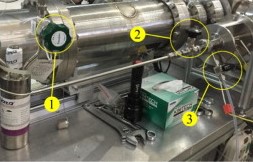

Experimental study of trimethyl aluminum decomposition

39. ZHANG Z etc. Experimental study of trimethyl aluminum decomposition[J]. Journal of Crystal Growth, 2017, 473: 6–10.

更新于:2017/12/19 -

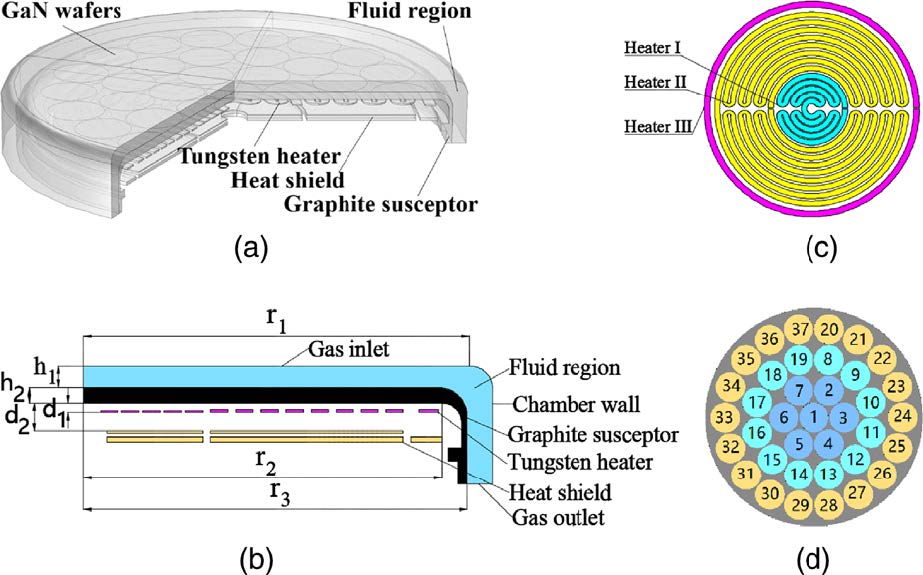

Species transport and chemical reaction in a MOCVD reactor and their influence on the GaN growth u…

38. Zhi Zhang, Haisheng Fang*, Qingxia Yao, Han Yan, Zhiyin Gan, Species transport and chemical reaction in a MOCVD reactor and their influence on the GaN growth uniformity", Journal of Crystal Growth 454 (2016) 87–95.

更新于:2017/09/26 -

Uniformity analysis of temperature distribution in an industrial MOCVD

37. Jiang Zheng, Haisheng Fang*, Zhi Zhang, Jinzhe Yang, Zhiyin Gan, Han Yan, "Uniformity analysis of temperature distribution in an industrial MOCVD", Cryst. Res. Technol., 1–10 (2016) / DOI 10.1002/crat.201600195.

更新于:2017/09/26 -

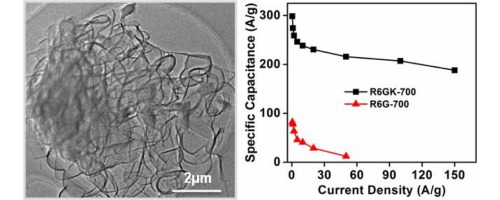

N-doped interconnected carbon sheets for energy storage application

36. Weiwei Ming, Haisheng Fang, Guang Feng*, "N-doped interconnected carbon sheets for energy storage application", Materials Research Bulletin, 2016, http://dx.doi.org/doi:10.1016/j.materresbull. 2016.08.023.

更新于:2017/09/26 -

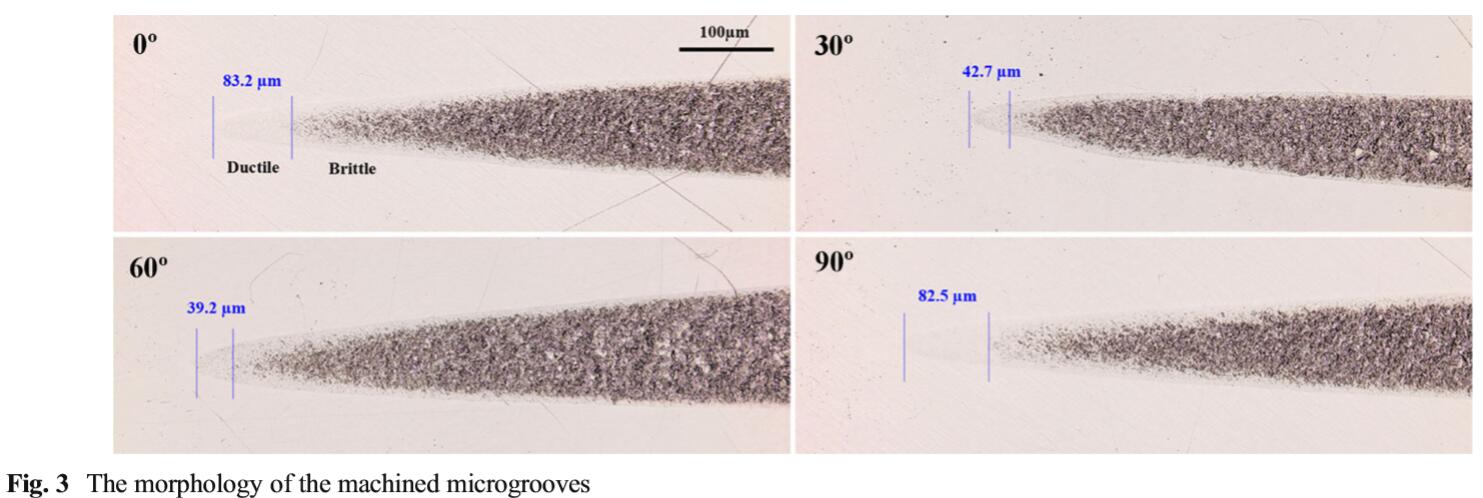

Influence of cutting parameters on the ductile-brittle transition of single-crystal calcium fluori…

35. Xiao Chen, Jianfeng Xu*, Haisheng Fang, Ruiji Tian, "Influence of cutting parameters on the ductile-brittle transition of single-crystal calcium fluoride during ultra-precision cutting", Int J Adv Manuf Technol, 2016, DOI 10.1007/s00170-016-9063-9.

更新于:2017/09/26 -

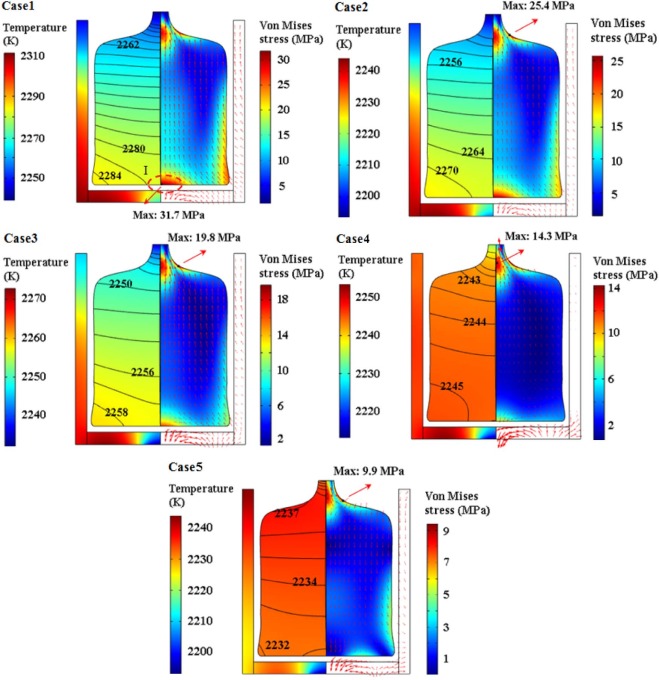

Dependence of thermal stress evolution on power allocation during Kyropoulos sapphire cooling proc…

34. Sen Wang, Haisheng Fang*, "Dependence of thermal stress evolution on power allocation during Kyropoulos sapphire cooling process", Applied Thermal Engineering, Volume 95, 25 February 2016, Pages 150–156.

更新于:2017/09/26 -

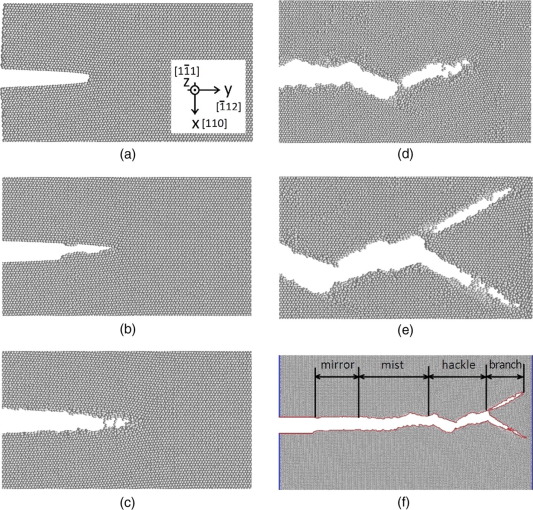

Numerical Scheme Analysis of Molecular Dynamics towards Accurate Prediction of Fracture Toughness …

33. Zhimin Jiang, Haisheng Fang*, Qianli Ma, Xiangang Luo, Zhenya Lv, Jianfeng Xu, Numerical Scheme Analysis of Molecular Dynamics towards Accurate Prediction of Fracture Toughness of Silicon, Engineering Fracture Mechanics 157 (2016) 11–25

更新于:2017/09/26 -

Uniformity investigation of MOCVD-grown LED layers

32. Zhimin Jiang, Han Yan, Sheng Liu, Zhi Zhang, Zhiyin Gan, Haisheng Fang*, Uniformity investigation of MOCVD-grown LED layers, Cryst. Res. Technol. 51, No. 1, 30–40 (2016) (Selected as Journal Cover Paper) 2015.

更新于:2017/09/26 -

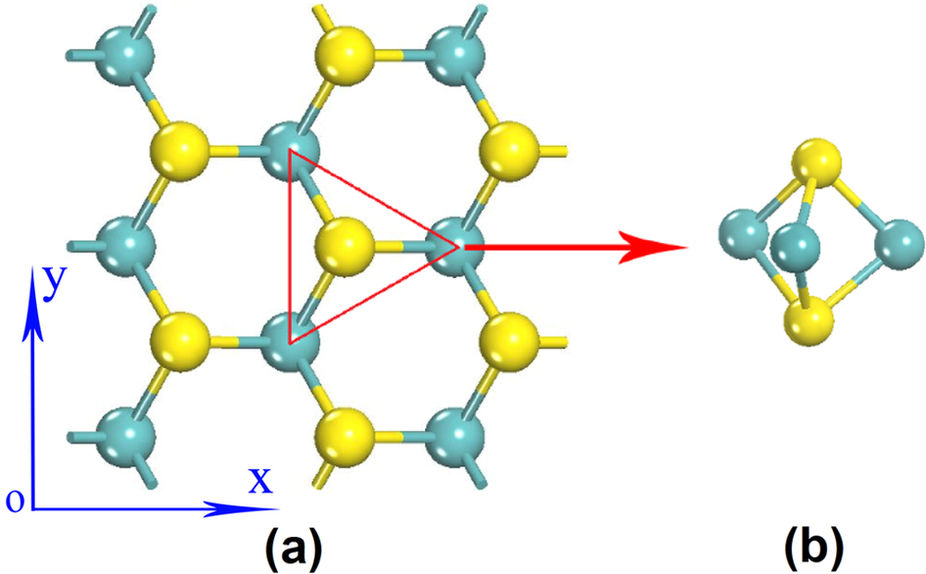

A Revisit to High Thermoelectric Performance of Single-layer MoS2

31. Zelin Jin, Quanwen Liao, Haisheng Fang*, Zhichun Liu*, Wei Liu, Zhidong Ding, Tengfei Luo, Nuo Yang*, A Revisit to High Thermoelectric Performance of Single-layer MoS2, Scientific Reports 5, Article number: 18342 (2015)

更新于:2017/09/26 -

Influencing factors of GaN growth uniformity through orthogonal test analysis

30. Zhi Zhang, Haisheng Fang*, Han Yan, Zhimin Jiang, Jiang Zheng, Zhiyin Gan, Influencing factors of GaN growth uniformity through orthogonal test analysis, Applied Thermal Engineering 91 (2015) 53-61

更新于:2017/09/26 -

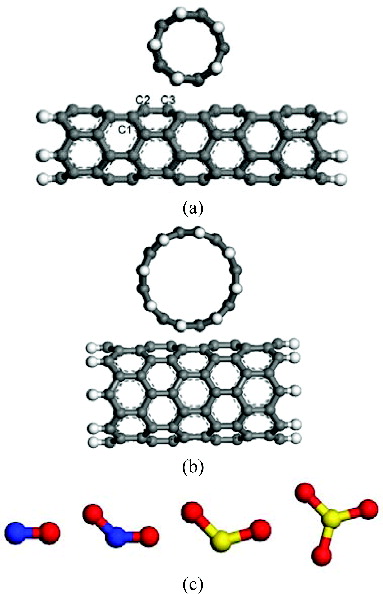

Adsorption Mechanism of Oxide Gas Pollutants by Single-walled Carbon Nanotubes

29. Z. M. Jiang, H. S. Fang*, Z. L. Jin, M. Y. Wang, Adsorption Mechanism of Oxide Gas Pollutants by Single-walled Carbon Nanotubes, Fullerenes, Nanotubes and Carbon Nanostructures 23(10) (2015), 890-898

更新于:2017/09/26 -

Analysis and optimization of Czochralski laser oxide crystal growth

28. H.S. Fang, J.Z. Lin, L.L. Zheng*, X.M. Huang, Analysis and optimization of Czochralski laser oxide crystal growth, International Journal of Heat and Mass Transfer 85 (2015) 505–512

更新于:2017/09/26 -

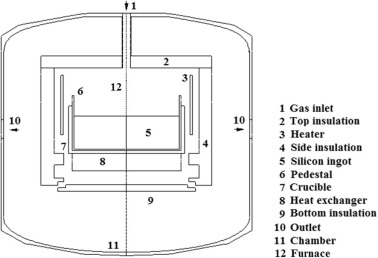

Gas flow optimization during the cooling of multicrystalline silicon ingot

27. S. Wang, H.S. Fang*, C.J. Zhao, Z. Zhang, M.J. Zhang, J.F. Xu, “Gas flow optimization during the cooling of multicrystalline silicon ingot”, International Journal of Heat and Mass Transfer 84 (2015) 370–375

更新于:2017/09/26 -

A novel MOCVD reactor for growth of high-quality GaN-related LED layers

26. Shaolin Hu, Sheng Liu, Zhi Zhang, Han Yan, Zhiyin Gan, Haisheng Fang*, A novel MOCVD reactor for growth of high-quality GaN-related LED layers, Journal of Crystal Growth 415 (2015), 72–77

更新于:2017/09/26 -

Systematic Study of Epitaxy Growth Uniformity in a Specific MOCVD Reactor

25. Haisheng Fang, Zhi Zhang, Yaoyu Pan, Ronghui Ma*, Mengying Wang, Systematic Study of Epitaxy Growth Uniformity in a Specific MOCVD Reactor, Cryst. Res. Technol. 49, No. 11, 907–918 (2014).

更新于:2017/09/26 -

Integrated Analysis and Design Optimization of Germanium Purification Process Using Zone-refining …

24. S. Wang, H.S. Fang*, Z.L. Jin, C.J. Zhao, L.L. Zheng*, Integrated Analysis and Design Optimization of Germanium Purification Process Using Zone-refining Technique, Journal of Crystal Growth 408 (2014) 42–48.

更新于:2017/09/26 -

Study of Internal Radiation with Solute Inclusions during Czochralski Sapphire Crystal Growth

23. H.S. Fang, Q.J. Zhang, J. Tian, S. Wang, R.H. Ma*, Study of Internal Radiation with Solute Inclusions during Czochralski Sapphire Crystal Growth, International Journal of Heat and Mass Transfer 79 (2014) 783–789.

更新于:2017/09/26 -

Influence of temperature-dependent thermophysical properties of sapphire on the modeling of Kyropo…

22. Z.L. Jin, H.S.Fang*, N.Yang, Z.Zhang, S.Wang, J.F.Xu, Influence of temperature-dependent thermophysical properties of sapphire on the modeling of Kyropoulos cooling process, Journal of Crystal Growth 405(2014), 52–58.

更新于:2017/09/26 -

Characteristics of melt convection during Kyropoulos sapphire crystal growth

21. H.S. Fang, Z. Zhang, Z.L. Jin, S. Wang, J.F. Xu, Characteristics of melt convection during Kyropoulos sapphire crystal growth, International Journal of Materials Research, Vol. 105, No. 10, pp. 961-967.

更新于:2017/09/26 -

Numerical optimization of czochralski sapphire single crystal growth using orthogonal design metho…

20. H. S. Fang, J. Tian, S. Wang, Y. Long, M. J. Zhang, and C. J. Zhao, Numerical optimization of czochralski sapphire single crystal growth using orthogonal design method, Crystal Research & Technology, Vol.49, Issue 5/2014, page 323-330.

更新于:2017/09/26 -

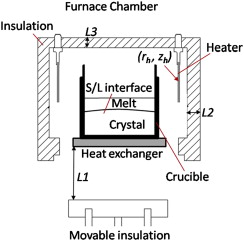

A modified cooling process in directional solidification of multicrystalline silicon

19. Naigen Zhou, Maohua Lin, Lang Zhou, Qiufa Hu, Haisheng Fang, Sen Wang, A modified cooling process in directional solidification of multicrystalline silicon, Journal of Crystal Growth 381 (2013) 22–26.

更新于:2017/09/26 -

Role of Internal Radiation at the Different Growth Stages of Sapphire by Kyropoulos Method

18. H.S. Fang, Z.L. Jin, M.J. Zhang, Z. Zhang, C.J. Zhao, Role of Internal Radiation at the Different Growth Stages of Sapphire by Kyropoulos Method, International Journal of Heat and Mass Transfer 67 (2013) 967–973.

更新于:2017/09/26 -

Crystal Cracking Analysis and Three-dimensional Effects during Kyropoulos Sapphire Growth

17. H.S. Fang, S. Wang, Z.L. Jin, J. Tian, J.F. Xu, Crystal Cracking Analysis and Three-dimensional Effects during Kyropoulos Sapphire Growth, Crystal Research & Technology 48 (9) (2013) 649–657.

更新于:2017/09/26 -

The approach of minimum heat consumption and its applications in convective heat transfer optimiza…

16. W. Liu, H. Jia, Z.C. Liu, H.S. Fang, K. Yang, The approach of minimum heat consumption and its applications in convective heat transfer optimization, International Journal of Heat and Mass Transfer 57 (2013) 389-396.

更新于:2017/09/26 -

Characteristics of thermal stress evolution during the cooling stage of multicrystalline silicon

14. H.S. Fang, Q.J.Zhang, Y.Y. Pan, S. Wang, N.G. Zhou, L. Zhou, M.H. Lin,Characteristics of thermal stress evolution during the cooling stage of multicrystalline silicon, Journal of Thermal stresses, 36(9), pp 947-961

更新于:2017/09/26 -

To investigate interface shape and thermal stress during sapphire single crystal growth by Cz meth…

13. H.S. Fang, Y.Y. Pan, L.L. Zheng, , Q.J. Zhang, S. Wang, Z.L. Jin, To investigate interface shape and thermal stress during sapphire single crystal growth by Cz method, Journal of Crystal Growth, Volume 363, 15 January 2013, Pages 25–32

更新于:2017/09/26 -

Study of melt convection and interface shape during sapphire crystal growth by Czochralski method

12. Haisheng Fang, Jun Tian, Quanjiang Zhang, Yaoyu Pan, Sen Wang, Study of melt convection and interface shape during sapphire crystal growth by Czochralski method, International Journal of Heat and Mass Transfer, Volume 55, Issues 25–26, December 2012, Pages 8003–8009

更新于:2017/09/26 -

Study and optimization of gas flow and temperature distribution in a Czochralski configuration

11. H.S. Fang, Z.L.Jin, X.M. Huang, Study and optimization of gas flow and temperature distribution in a Czochralski configuration, Journal of Crystal Growth, Volume 361, 15 December 2012, Pages 114–120

更新于:2017/09/26 -

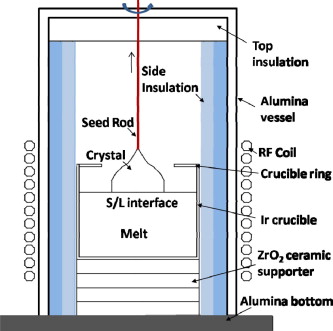

Integrated Study of Lead Iodide Crystal Growth and Doping Processes

10. Haisheng Fang, Sen Wang, YuQiang Zeng, Zhengbin Guo, Integrated Study of Lead Iodide Crystal Growth and Doping Processes, International Journal of Heat and Mass Transfer, 55 (2012) 4469–4475.

更新于:2017/09/26 -

Influence of furnace design on the thermal stress during directional solidification of multicrysta…

9. H.S. Fang, S. Wang, L. Zhou, N.G. Zhou, M.H. Lin, Influence of furnace design on the thermal stress during directional solidification of multicrystalline silicon, Journal of Crystal Growth, volume 346, 5–11, 2012

更新于:2017/09/26 -

Hot zone design for controlled growth to mitigate cracking in laser crystal growth

8. Hui Zhang, Lili Zheng, Haisheng Fang, Hot zone design for controlled growth to mitigate cracking in laser crystal growth, Journal of Crystal Growth, 318, 695–699, 2011

更新于:2017/09/26 -

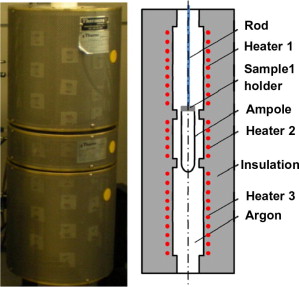

Numerical Study of the Micro-Pulling-Down Process for Sapphire Fiber Crystal Growth

7. H.S.Fang, E.D.Bourret, Z.W.Yan, Numerical Study of the Micro-Pulling-Down Process for Sapphire Fiber Crystal Growth, Crystal Growth & Design, Vol. 11, No. 1, 2011

更新于:2017/09/26 -

The Effects of Wind and Posture on the Aerodynamic Performance During the Flight Stage of Skiing

6. Zhifeng Chen, Haisheng Fang*, The Effects of Wind and Posture on the Aerodynamic Performance During the Flight Stage of Skiing, ASME-Journal of Biomechanical Engineering, Vol. 133, 2011, 091001-1

更新于:2017/09/26 -

Analysis of limits for sapphire growth in a micro-pulling-down system

5. Gaurab Samanta, Andrew Yeckel, Parthiv Daggolu, Haisheng Fang, Edith D. Bourret-Courchesne, Jeffrey J. Derby, Analysis of limits for sapphire growth in a micro-pulling-down system, Jourrnal of Crystal Growth, Volume 335, Issue 1, Pages 148–159 ,2011

更新于:2017/09/26 -

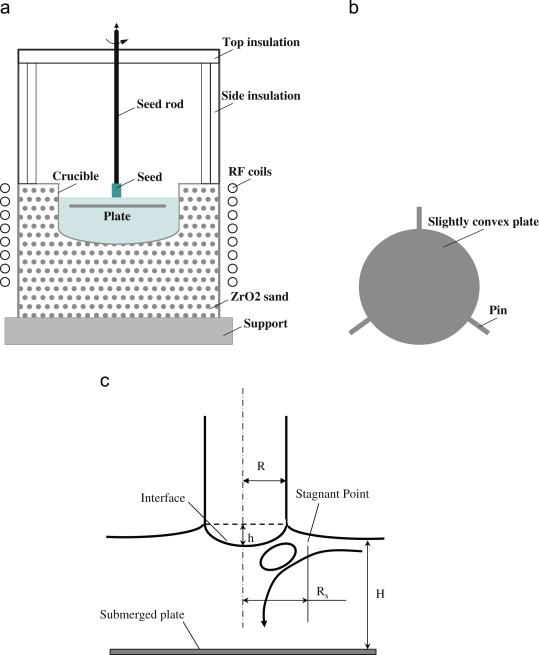

Nd:YVO4 crystal growth by Czochralski technique with a submerged plate

4. H. Zhang, H.S. Fang, L.L. Zheng, Z.G.Wu, G.C.Zhang, Nd:YVO4 crystal growth by Czochralski technique with a submerged plate, Journal of Crystal Growth, Volume 311, 4652–4659, 2009

更新于:2017/09/26 -

Simulations of Droplet Spreading and Solidification Using an Improved SPH Method

3. H.S. Fang, K. Bao, J.A. Wei, H. Zhang, E.H. Wu, and L.L. Zheng, Simulations of Droplet Spreading and Solidification Using an Improved SPH Method, Numerical Heat Transfer, Part A, 55: 124–143, 2009

更新于:2017/09/26 -

Optimization of the cooling profile to achieve crack-free Yb:S-FAP crystals

2. H.S. Fang, L.L. Zheng, S. R. Qiu, K.I. Schaffers, J.B. Tassano, H. Zhang, Optimization of the cooling profile to achieve crack-free Yb:S-FAP crystals, Journal of Crystal Growth, Volume 310, Issue 16, Pages 3825-3832, 2008

更新于:2017/09/26 -

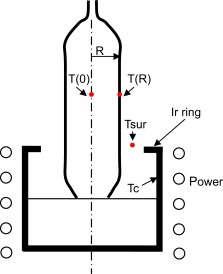

To Reduce Melt Inclusion using Submerged Heater and Baffle in Optical Crystal Growth

1. Fang, H. S., Zheng, L. L., Zhang, H., Y. Hong, and Q. Deng, To Reduce Melt Inclusion using Submerged Heater and Baffle in Optical Crystal Growth, Crystal Growth & Design, Vol. 8, pp. 1840-1848, 2008

更新于:2017/09/26

![[Physical Review Fluids] Electric-Field-Mediated Jet Formation from the Bubble Bursting above a Free Surface at Low Ohnesorge Number](/__local/F/BF/9B/6A396B066A6CF3D0A9D86AEF4F5_FFEEFC67_40AB.jpg)

![[Physics of Fluids] The Maximum Spreading of a Shear-Thinning Fluid Droplet Impacting on Solid Surfaces](/__local/A/BA/A3/2F8D13A857CF27CC305490B777C_ABEF66D4_603E.jpg)

![[International Communications in Heat and Mass Transfer] Solidification Process of Hollow Metal Droplets Impacting a Substrate](/__local/D/CC/7B/080856F9E9CD51C0833B034E0C5_1DD7D059_8418.jpg)

![[Surface and Coatings Technology] Improvement of Titanium Film Uniformity by Magnetron Sputtering with Electromagnetic Coil Design](/__local/3/02/EE/52E9B5BE5E142B580C6D2E86665_9AD3FB6C_9994.jpg)

![[Journal of Fluid Mechanics] Modelling the First Droplet Emission from an Electrified Liquid Meniscus Hanging at the Nozzle Tip](/__local/9/C2/87/38C7CDA5E82F53E392424C365AA_8E7686DC_80B8.jpg)

![[International Journal of Heat and Mass Transfer] Effect of Substrate Temperature on the Deformation of Liquid Metal Droplets during Spreading and Solidification](/__local/5/7D/B6/6A83B7B9C84C39FE8BA45C680C4_A23DF32A_BA4C.jpg)

![[Journal of Non-Crystalline Solids] Effects of Annealing on Thermal Stress Generation during the Cooling Process of Large-Size Silica Glass](/__local/5/3F/0B/65822F18DF92C0AEAFB47089FBA_37E7D96D_1E52B.jpg)

![[Crystal Research and Technology] Analysis of Influencing Factors on Silicon Epitaxial Growth in Horizontal Single-Wafer Reactor through Orthogonal Test](/__local/0/E7/C7/36FF3BD22E95339449FE1A30CF9_0DB225A9_C052.jpg)

![[Surface and Coatings Technology] Copper Target Erosion during Unbalanced Magnetron Sputtering under Different Electromagnetic Fields](/__local/8/E2/E1/E0336614287F9C4E57ACD729C9A_277B51BF_5395.jpg)

![[International Journal of Applied Glass Science] Modeling and Optimization of the Sagging Process for Large-Size and High-Purity Silica Glass Synthesis](/__local/7/C3/A7/057FD79D24FFB6951608F2A7B13_489604FD_EA7F.jpg)

![[Applied Surface Science] Monte Carlo simulation of deposition uniformity in the triple-target magnetron co-sputtering system](/__local/5/AA/5D/8DAD6454EE82BAD89B6EECE1C26_8051C2A4_3A9B.jpg)

![[Ceramics International] SiO2 soot preform sintering process for the synthesis of large-size and high-purity silica glass](/__local/C/98/6B/8581FD84F19C68D718FAFEC2C01_906FB1DF_9E2D.jpg)

![[Journal of Fluid Mechanics] Electrohydrodynamic-induced partial coalescence between a droplet and a liquid–air interface](/__local/4/44/42/4E7D9113E18E52F2FB0FF639B20_66677C54_DC57.jpg)

![[Applied Thermal Engineering] Numerical study of a novel concentrator photovoltaic-membrane distilled plate-type seawater desalination structure Cooling channel](/__local/6/F6/61/70A898D4B3D967A5A45C03CFA1F_E6DEE45F_B7AD.jpg)

![[Journal of the American Ceramic Society] Effects of injection conditions on temperature and component distributions in a CVD furnace for large-size silica glass](/__local/C/FC/C3/475566589E83208706640B4C813_A20323F6_4A18.jpg)

![[Energies] Cooling Optimization Strategy for a 6s4p Lithium-Ion Battery Pack Based on Triple-Step Nonlinear Method](/__local/D/F2/FB/0A16BC716527E4DAEF4A18462CB_C6C65FCF_81C2.jpg)

![[Journal of Energy Research] Analysis of prismatic lithium-ion battery degradation based on an electrochemical-thermal-degradation model](/__local/B/11/4C/134AEA61C53BCC09DA2F725C5F9_434B880B_7C89.jpg)

![[Physics of Fluids] Predicting the lifetimes of evaporating droplets in ordered arrays](/__local/3/DC/5D/7063C3818F3EC3B0D9E2A1A09A7_6A44DCD2_14725.jpg)

![[Crystal Research and Technology] Study of Dislocation Bending During Film Growth by a Multiscale Scheme](/__local/0/C4/D1/3DCEBC19173E063004C57A3B09D_CDCEFECB_1BA9C.png)

![[Physics of Fluids] Probing the coalescence of non-Newtonian droplets on a substrate](/__local/C/4B/26/FAF628FFCBDB13FA3DEA93A0755_3A498AD4_A08B.png)

![[Physics of Fluids] Stability of line shapes in inkjet printing at low substrate speeds](/__local/5/E9/BD/A94F5A7AD78C6B613D4B76A03DB_A577F8CE_6FFD.png)

![[International Journal of Heat and Mass Transfer] Mechanism study on spreading dynamics of nanofluids droplet coupled with thermal evaporation](/__local/C/D2/35/391C1CD985A1978862D8A164793_BCE4F64C_255D7.png)